#10 x 2½" 316 Marine Grade Stainless Steel Deck Screws

#10 x 2½" 316 Marine Grade Stainless Steel Deck Screws

Couldn't load pickup availability

USE 316 GRADE STAINLESS STEEL FASTENERS!

Do you live in a salty or humid environment such as a house by the ocean? 316 marine grade stainless steel screws are the only option if you want your deck or jetty to last years in these environments.

Why 316 grade stainless steel?

316 grade stainless steel screws are favored due to their corrosion resistance and durability in all outdoor conditions. This steel variant offers the best protection in corrosive environments, which makes it suitable for marine or coastal applications. It is called "marine grade" for a reason. The high quality of 316 grade fasteners ensures long-term reliability with minimal maintenance which makes it the first choice for builderas and contractors working in salty or otherwise corrosive climates.

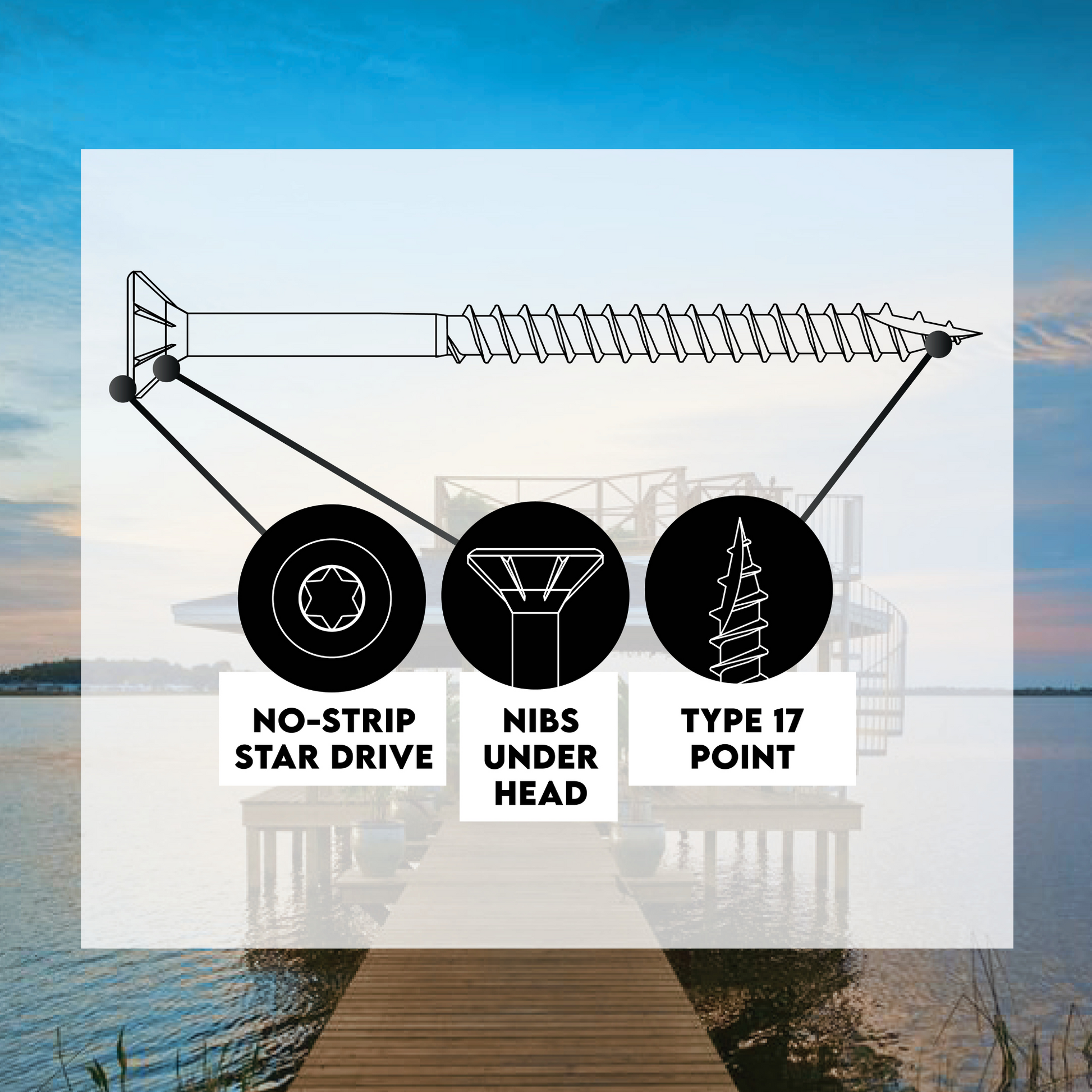

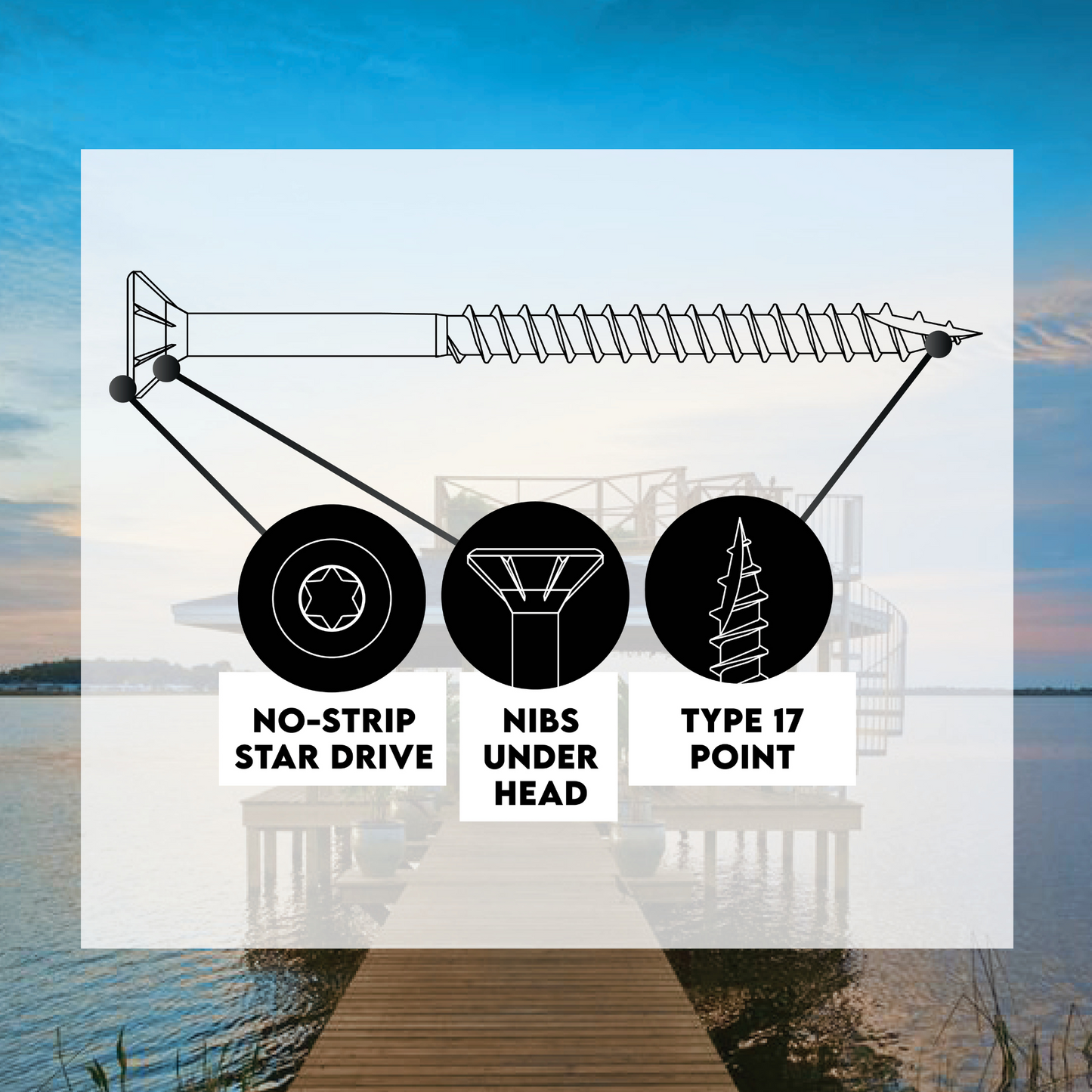

Benefits of star (torx) drive

The torx drive's six-point star design makes for easy driving with minimal cam-out. The torx head also makes for better torque transfer as the driver is less likely to pop out as it does with more traditional traditional pozi drive screws. This makes it a preferred choice in decking, fencing and general woodworking project where the head is exposed as the finish looks better and becomes a feature in the work.

FAQ

What is the difference between 304 and 316 grade stainless steel deck screws?

Both 304 and 316 stainless steel screws are corrosion resistant, but 316 stainless steel is called "marine grade" for as reason as it is more resistant to rusting and corroding in marine or coastal areas.

Are these screws suitable for saltwater environments?

Yes, 316 (marine grade) stainless steel deck and wood screws are suitable for use in marine and saltwater environments.

What is the lifespan of stainless steel deck screws?

Stainless steel is known for strength and durability in all weather conditions. Even after being submerged in salty water, 316 grade stainless steel comes out unscathed. These screws can last for many years without any significant corrosion or degradation and often outlast the structure that they were used to build.

Which grade is better for outdoor applications, 304 or 316?

Both grades can be used outdoors, but 316 is preferred for areas with high corrosion potential, such as coastal environments.

Subscribe to our emails

Be the first to know about new collections and exclusive offers.

- Choosing a selection results in a full page refresh.

- Opens in a new window.